EUV / XUV imaging & metrology

Application

Our digital age is being influenced by significant trends such as artificial intelligence (AI), 5G, virtual and augmented reality, and cloud services. With almost 40 billion connected devices world-wide, distributed computation and data storage will become increasingly important. To meet this growing demand, the energy, cost and time of electronic computations needs to be reduced by shrinking the size of transistors on microchips. This is where powerful EUV photolithography systems come into play. These systems operate at wavelengths as short as 13.5 nm, enabling the creation of 3-dimensional integrated circuits on the few-nanometer scale.

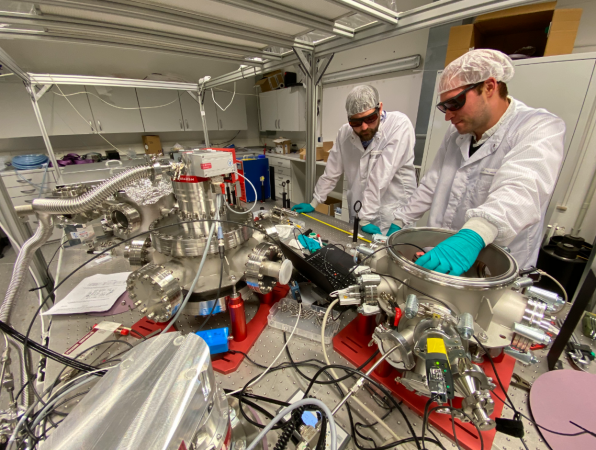

A major bottleneck for process optimization with extreme accuracy and speed is lack of precise and fast metrology tools inspecting chip quality during production. This is limiting large chip production throughput at high cost. Brilliant EUV sources based on laser-driven HHG enable inspection and metrology concepts being developed with the following key targets:

- Few-nanometer wavelength for matching the scale of integrated devices

- High brightness for fast measurements and high accuracy

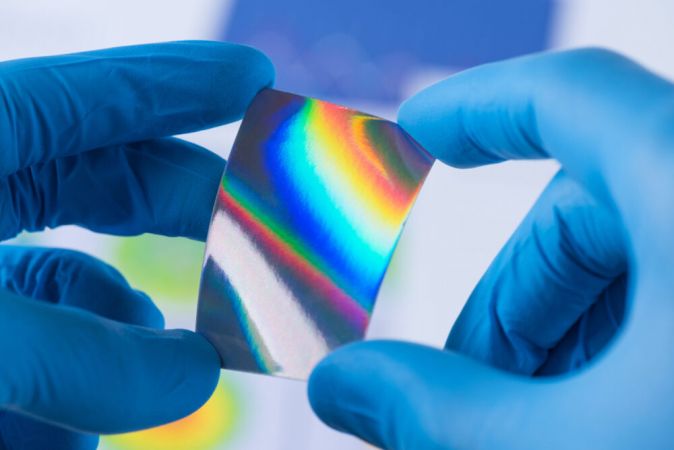

- Broad spectral bandwidth for material contrast

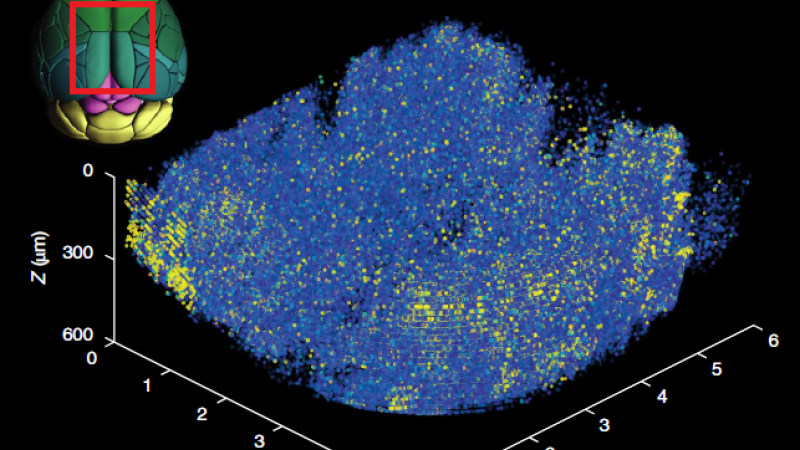

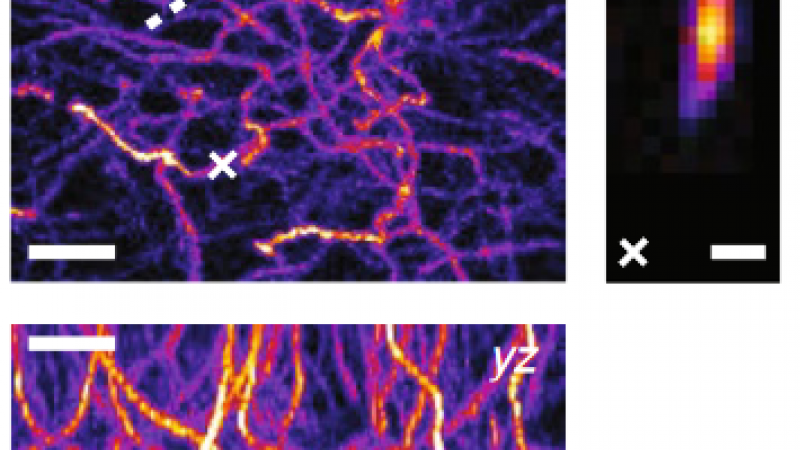

- High spatial coherence for lens-less nano-imaging concepts, such as coherent diffractive imaging (CDI), ptychrography, or EUV tomography

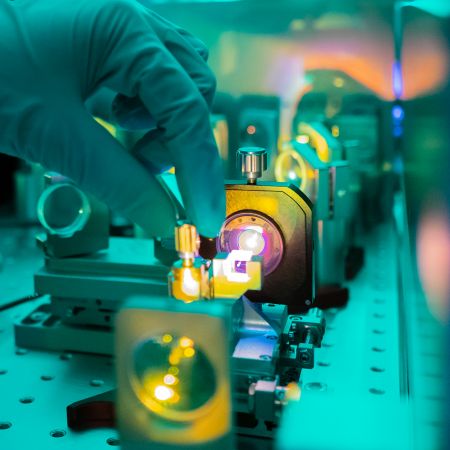

Table-top EUV sources

High harmonic generation (HHG) is a nonlinear optical process in which high-frequency light is generated from an intense laser pulse interacting with a gas, liquid, or solid target. The process involves the absorption of multiple photons from the laser pulse, followed by the re-emission of a single photon at a much higher frequency. This results in the generation of a broadband spectrum of typically odd harmonics of the driving laser frequency, which can extend into the extreme ultraviolet (XUV) and soft x-ray regimes. HHG is a key enabling technology for many scientific and industrial applications, such as spectroscopy, microscopy, and attosecond science.

Publications

-

March 21, 2022T. Golz, S. Starosielec, J. H. Buss, P. Merkl, E. Zapolnova, M. Schulz, M. Petev, M. J. Prandolini, and R. Riedel, “The ELI-ALPS MIR-HE Laser System – Design and Status,” in Optica High-brightness Sources and Light-driven Interactions Congress 2022, Technical Digest Series (Optica Publishing Group, 2022), paper MTh5C.3.

-

February 21, 2020Femtosecond 100 W-level OPCPAs from near-IR to short-wave-IR wavelengths,” Proc. SPIE 11259, Solid State Lasers XXIX: Technology and Devices, 112591F